I’ll tell the story of how a soldering station found its way into my workshop.

For quite some time, I’d been toying with the idea of making my own earbuds with wooden shells. Over the years, I’ve collected a wide variety of wood species from all around the world, so it would be wonderful to finally apply that natural beauty to earbud design as well. Since I mostly use the undeservedly forgotten wired classic flat-headed earbuds, I decided to build that exact type. At first just for myself — and if the result turns out well, perhaps to start making them available to the flat-head earbud community

Although woodworking isn’t new to me, this project has proven to be a real challenge — far more complex than I initially expected. I usually work with fairly basic tools, but this time the required precision went way beyond that, and not only because these earbuds measure just a few centimeters. Both housings (left and right) must be not only aesthetically perfect but also identical in shape and internal volume, while all vent holes need to be exactly the same size and in precisely the same position. Achieving that level of accuracy by hand is simply impossible.

Still, I gave it a shot and chose a compromise for the first prototype: a two-part shell with a metal front (for mounting the driver) and a wooden back serving as a low-frequency acoustic chamber. The wooden section was first cut on a laser and then finished by hand with tiny files. For acoustic reasons, I chose the hardest woods my laser could handle: Brazilian rosewood and African blackwood, which happened to match perfectly.

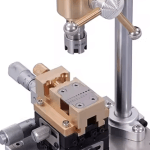

The prototype showed that even laser cutting isn’t ideal for this kind of work — even when cutting or engraving pieces from the same block of wood, results can vary slightly, simply because wood is not a uniform material. So for the future there is really only one viable solution: CNC milling.

Even so, this prototype served its purpose — it captures my vision for one of the upcoming models, which will have a fairly substantial shape to reveal as much wood grain as possible. My aim is to create earbuds that are not only audio devices but also style accessories — the rear plate will be almost like a piece of jewelry. One main model with countless design variations for different tastes.

The current prototype isn’t as comfortable as I hoped — a bit too heavy and too bulky — so once the CNC machine is up and running, a lot of experimentation awaits. Although the prototype is fully functional, I still haven’t decided on the final speaker driver, as I currently have more than 30 candidates for testing. Once a desktop CNC mill finally arrives in the workshop, I’ll have a much clearer picture of what is possible. I might even stick with the current concept — a combination of wooden and brass shell.

For now, I’m diving into learning — I’ve never worked with 3D modeling before. Hopefully, in about six months I’ll be able to share something truly noteworthy.